In today’s highly competitive furniture manufacturing industry, efficiency and precision are the bottom line for survival. For any panel furniture or custom furniture factory, the first process often determines the fate of the final product. This process is panel cutting, and the core equipment for performing this process is the panel saw.

Many factory owners face a dilemma when expanding production or upgrading equipment: should they choose a standard panel saw or upgrade to a fully automatic CNC panel saw? This guide will break down the selection logic to help you make the wisest long-term investment decision.

Why the Panel Saw is the Core Equipment in Modern Furniture Manufacturing?

Panel Saw in Modern Furniture Manufacturing

In the furniture production chain, panel processing is an interconnected process. If the first cut is crooked or the edge chipped, the subsequent edge banding machine cannot achieve a perfect fit, and the CNC drilling machine’s hole positions will also be off. The ultimate result is assembly difficulties and products being returned by customers.

As the industry transitions from traditional handcrafting to industrialisation, the requirements for panel cutting have undergone a qualitative change. The current market demands extremely high dimensional consistency, perfect cut quality, and extremely fast delivery cycles. Traditional manual table saws can no longer meet these high-intensity industrial demands. Therefore, high-performance panel saws are no longer an option, but a necessity that determines a factory’s profitability. They directly define the factory’s capacity ceiling and quality baseline.

What is a Panel Saw? Basic Concepts and Application Scenarios

A panel saw is an industrial piece of equipment specifically designed for precisely cutting large-format panels such as particleboard, MDF, and plywood into furniture component sizes.

Unlike table saws operated by amateur woodworkers, industrial panel saws are designed for high-volume, high-load production environments. Its core working principle typically involves two key parts: the main saw blade cuts the panel, while the scoring blade, located in front of the main saw, pre-cuts a shallow groove on the bottom of the panel. This dual-blade structure is a key technology for preventing chipping at the bottom of the board, ensuring perfect cut quality on both sides.

In a typical panel furniture production line, the panel saw is located between the raw material warehouse and the edge banding process. It acts as the pacemaker of production, its output speed directly determining the efficiency of the entire production line. Whether producing wardrobes, cabinets, or office furniture, the consistent performance of this machine is crucial.

Comparison of Main Types and Applicable Scenarios of Panel Saws

The market offers a wide variety of equipment, from simple auxiliary devices to complex automated centres. Understanding the characteristics of different types is the first step in selection.

Standard Panel Saw (Entry-Level Application)

This type of equipment typically refers to a precision sliding table saw. It is suitable for small, newly established furniture factories or as an auxiliary prototyping device in large factories. Although it relies on manual feeding and positioning, high-quality models still provide good cutting accuracy.

Advantages and Target Audience of CNC Panel Saws

When factories expand and have higher requirements for precision and repeatability, the CNC panel saw becomes the mainstream choice. By controlling the stop and cutting stroke through a CNC system, it eliminates human reading errors. This equipment is ideal for medium-sized furniture manufacturers, ensuring quality while moderately improving efficiency.

The Value of Automatic Panel Saw in Efficiency Improvement

Automatic panel saws (usually referring to electronic panel saws or beam saws) introduce automatic feeding clamps and beam clamping systems. The operator simply pushes the board into the worktable, and the machine automatically positions, clamps, and completes the cutting cycle. It significantly reduces reliance on skilled workers, supports continuous production, and is a powerful tool for increasing capacity.

Industrial Panel Saw for Large-Scale Furniture Production

For factories that need to process hundreds or even thousands of boards daily, industrial panel saws are the only option. These machines are designed with heavy-duty construction, support stack cutting of multiple boards, and can operate under high loads for extended periods, supporting extremely high production rates.

To facilitate your comparison, we have compiled the following table:

- Type Ideal For Key Advantage Automation Level

- Standard Sliding Table Saw Small workshops, prototyping Low entry cost, flexibility Low (Manual)

- CNC Panel Saw, Medium-sized factories, High precision, programmable Medium

- Automatic Panel Saw Volume production, Reduced labour, speed High

- Industrial Beam Saw Mass manufacturing Maximum throughput, stack cutting Very High

Key Factors to Consider When Choosing a Panel Saw for Furniture Manufacturing

Before communicating with a panel saw machine manufacturer, you need to assess your actual needs.

Panel Type and Processing Size Requirements

Do you primarily process easily chipped melamine-faced panels or extremely hard plywood? Do you need to cut extra-large panels? These factors determine the power of your main motor and whether you require a special air-floating table to protect the panel surface.

Cutting Accuracy and Production Consistency

Accuracy is not just about straight cuts, but also about tolerance control over long-term operate. A high-quality panel saw should employ a high-rigidity structure and a high-precision servo drive system to ensure cutting position accuracy meets industrial-grade standards. This is the foundation for ensuring the smooth operation of subsequent processes.

Production Efficiency and Order Delivery Capability

Don’t just look at the machine’s maximum speed; look at the actual output per shift. The Automatic panel saw’s automatic positioning and high-speed return design can significantly shorten the time of a single cutting cycle. If your order volume is growing rapidly, be sure to reserve capacity for expansion.

Automation and System Integration Capabilities

This is the most critical consideration for modern factories. Does the equipment you choose support Manufacturing Automation? Can it interface with your design and order splitting software? Can it be integrated into a future complete panel processing system? Isolated equipment will become information silos in the future.

Long-Term Operating and Maintenance Costs

Equipment stability directly affects maintenance costs. The downtime losses caused by a cheap piece of equipment that frequently shuts down far exceed the price difference of the equipment itself.

The Role of Panel Saw in Manufacturing Automation

In the era of Industry 4.0, the panel saw is no longer an isolated entity, but the intelligent starting point for automated furniture production lines.

Advanced automatic panel saws can seamlessly connect with intelligent panel storage systems, enabling unmanned operation from material picking to cutting. After cutting, it can also automatically transfer the panels to edge banding machines and drilling centres via robotic arms or rotary lines. This highly integrated Manufacturing Automation model not only significantly reduces labour costs but also enables full-process traceability of production data. Upgrading from single-machine operations to complete panel processing lines is an essential path for furniture factories to grow and thrive.

Common Misconceptions: Common Mistakes Furniture Factories Make When Choosing Panel Saws

Focusing solely on price, ignoring long-term capacity: Many factories choose low-end equipment to save money, only to find that as orders increase, the equipment’s capacity reaches its limit, forcing them to repurchase after a year, resulting in even greater cost waste.

Ignoring automation compatibility: Purchasing “dumb machines” that don’t support data integration prevents the factory from implementing information management, forcing it to rely on manual data input, leading to high error rates and labour costs.

Mismatch between selection and process: Factories primarily producing customised furniture (many single-piece batches) mistakenly purchase equipment only suitable for engineering orders (large batches), resulting in extremely low changeover efficiency.

How to Choose a Reliable Panel Saw Machine Manufacturer

Choosing a panel processing machine is essentially choosing a partner. A superior panel saw machine manufacturer should possess the following qualities:

Manufacturing Experience and Industry Focus: Do they have deep expertise in the furniture industry? Do they truly understand the challenges of panel processing?

Product Line Completeness: Does it have a complete product line covering CNC panel saws to industrial panel saws to meet your development needs at different stages?

Automation Mindset: Does it possess a Manufacturing Automation perspective? Can it provide you with complete production line planning advice, rather than just selling a single machine?

Service and Global Support: Machines will always encounter problems; the key is after-sales response speed and spare parts supply capabilities.

Why More and More Furniture Manufacturers Choose Caelus Panel Saw

Among many brands, Caelus has become the industry’s preferred choice due to its profound understanding of furniture manufacturing processes. Caelus not only provides equipment but also offers comprehensive panel processing solutions.

Solutions Focused on Furniture Manufacturing

Caelus understands the pain points of furniture factories. Both the entry-level Pilot series and the high-end Aurora series utilise a high-rigidity structure and a high-precision servo system. This means that even the entry-level models offer industrial-grade cutting precision, ensuring worry-free edge banding and drilling processes.

Panel Saw Product Line Covering Multiple Needs

Caelus’ product matrix is scientifically designed to perfectly match the needs of factories of different sizes:

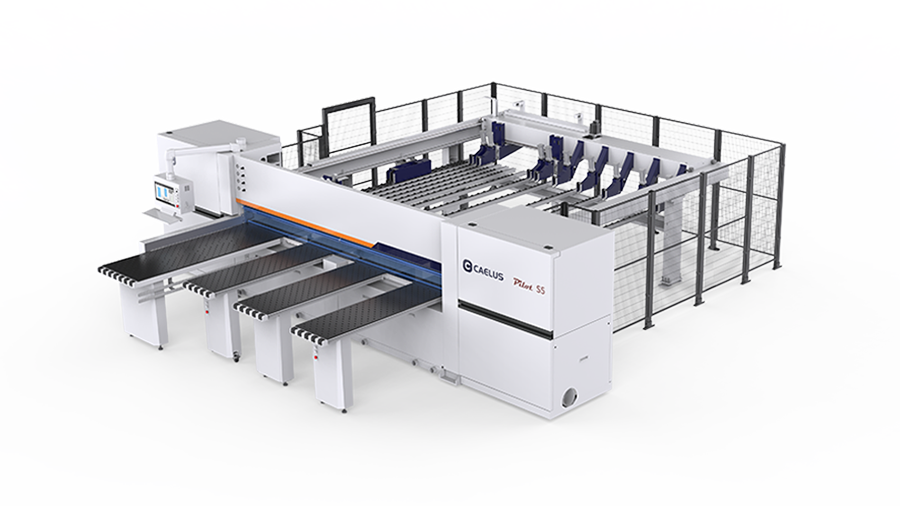

Pilot Series (Pilot S3 / Pilot S5): This is the ideal starting point for standard automated production. It combines high cost-effectiveness with intelligent control, allowing small and medium-sized factories to easily achieve the efficiency of an automatic panel saw.

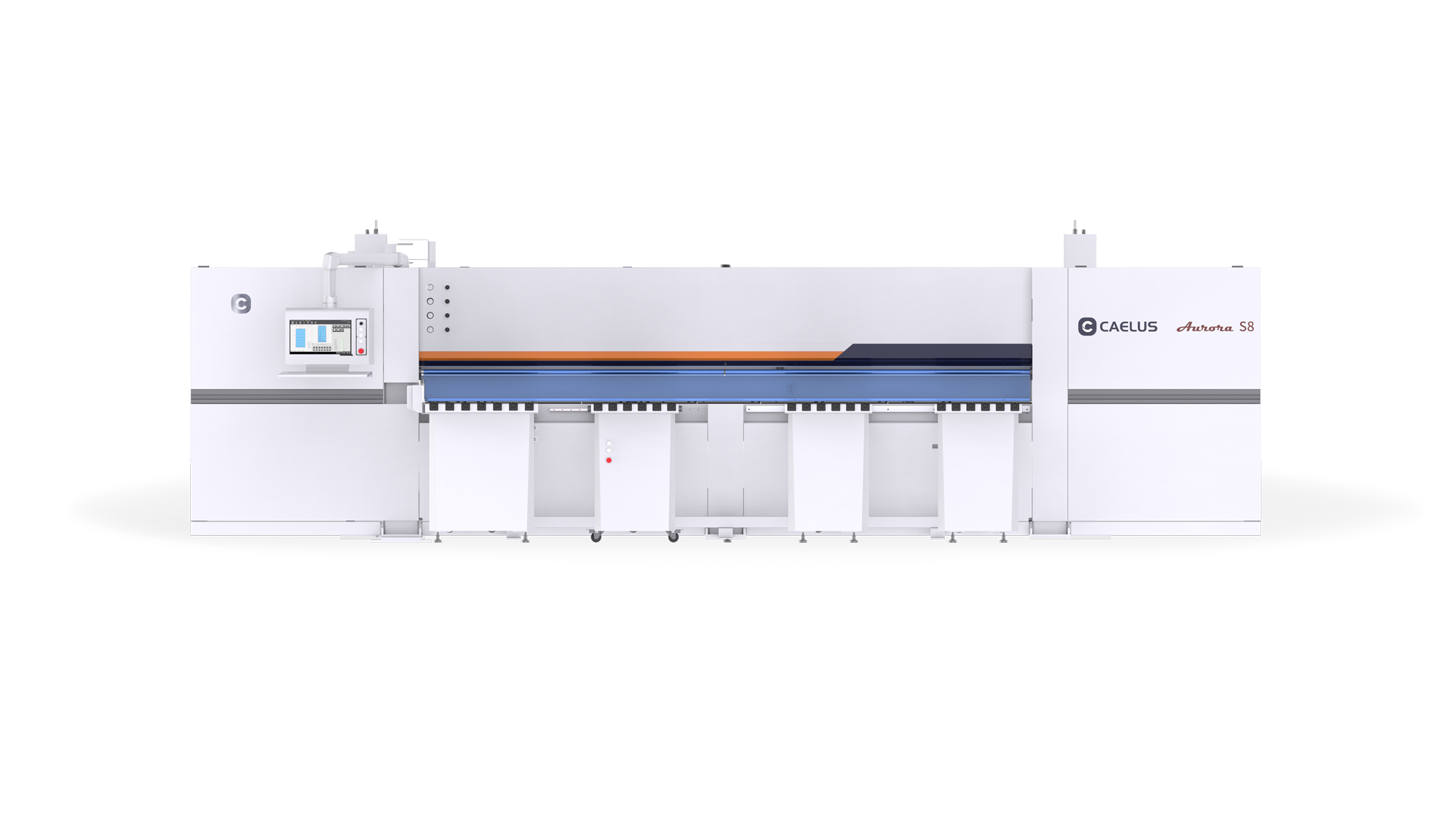

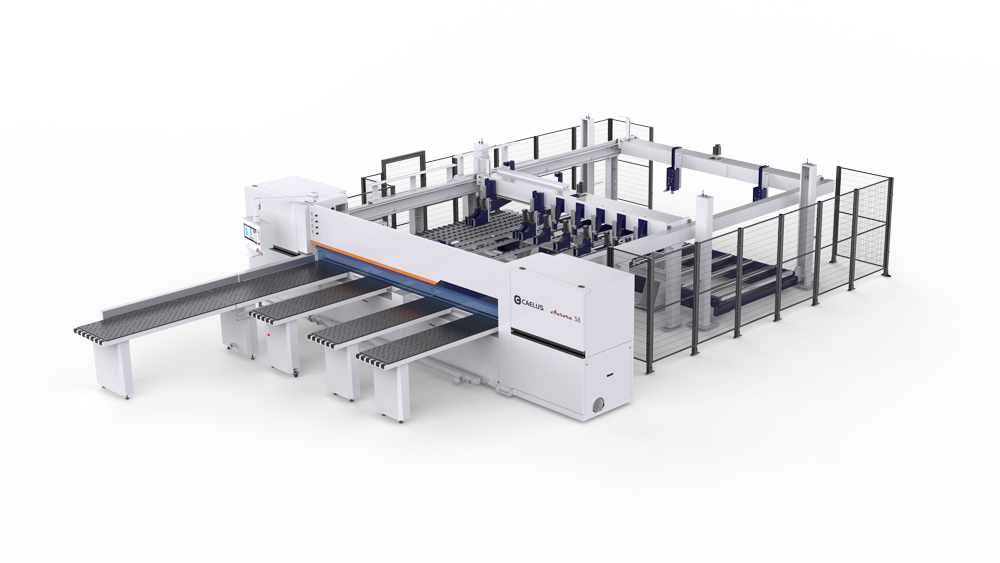

Aurora Series (Aurora S6 / Aurora S8): It designed for high performance and high automation needs. This series of industrial panel saws boasts faster cutting speeds and a more powerful drive system, making it a mainstay in large smart factories.

Bespoke (SawTekRob 5): As a flexible cutting centre, it enables automatic rotation of the sheet material and integration of multiple processes, representing the ultimate form of a true CNC panel saw.

Caelus’s all-around capabilities for Manufacturing Automation are built into its intelligent features. The standard optimised software supports automatic path planning and seamlessly integrates with MES and warehouse systems (such as StoreTek 5). This means that choosing Caelus provides a perfect interface for future Manufacturing Automation upgrades.

Conclusion: Choosing the right panel saw for furniture manufacturing is a long-term investment.

A panel saw is much more than just a wood-cutting machine; it’s the cornerstone of the entire furniture manufacturing process. The right selection not only improves current production efficiency but also reduces long-term operating costs and enhances a company’s market competitiveness. When making a decision, be sure to consider both current production capacity needs and development plans for the next 3-5 years. Choosing a panel saw machine manufacturer like Caelus, with a Manufacturing Automation vision and a complete product line, will help you stay ahead in the fierce market competition.