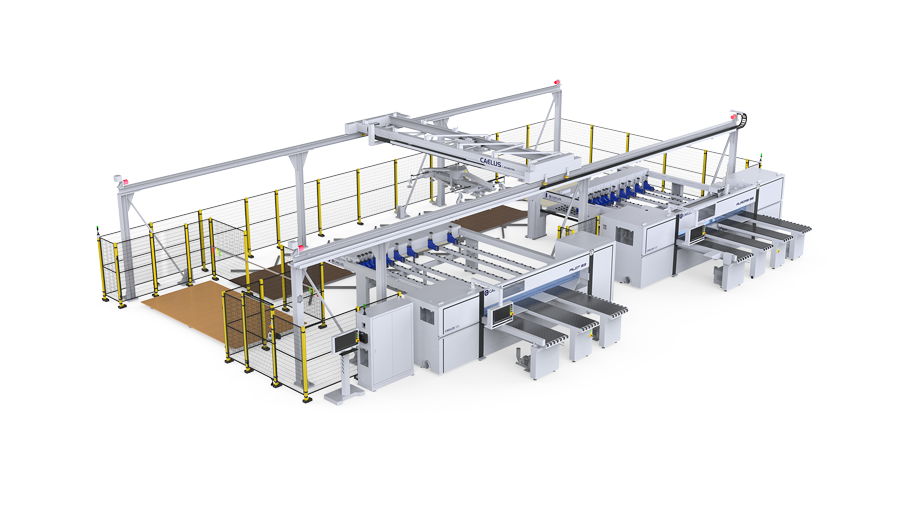

Caelus provides intelligent machine covering the entire panel furniture production process, including core panel machines such as the Panel Saw, Auto Panel Storage, and Edge Bander. Through high-performance CNC machines and automated control technology, Caelus offers furniture manufacturing plants efficient, high-precision, and flexible panel processing solutions compatible with various product types, helping companies move towards intelligent and digital production.

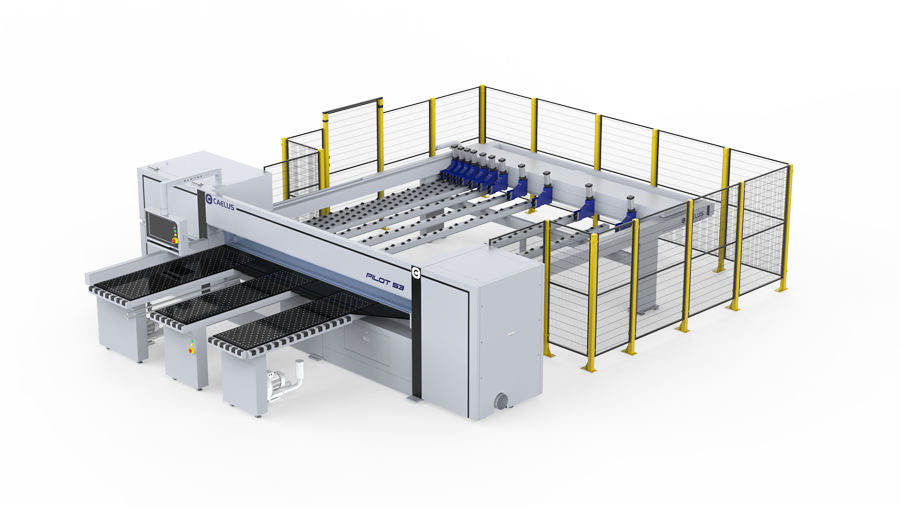

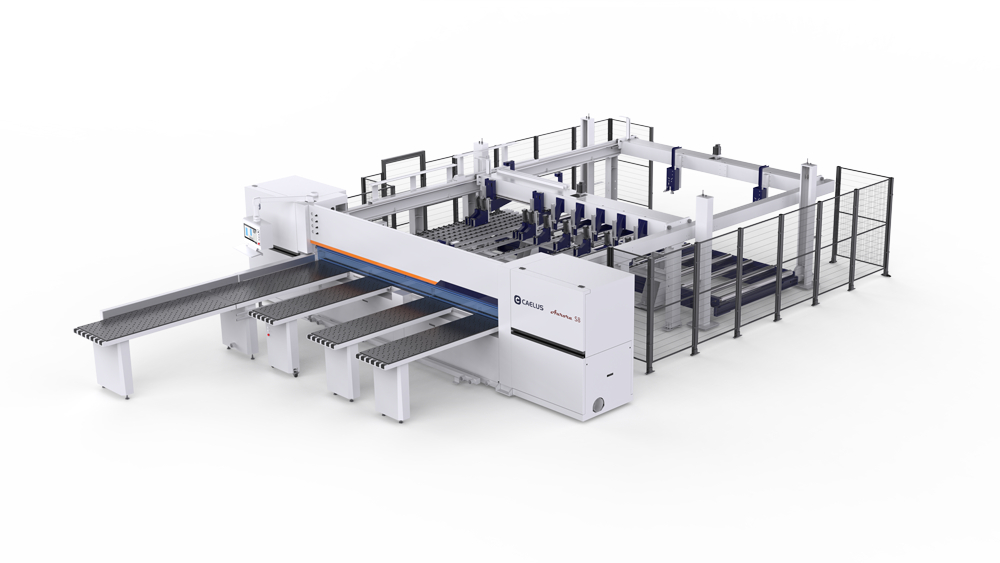

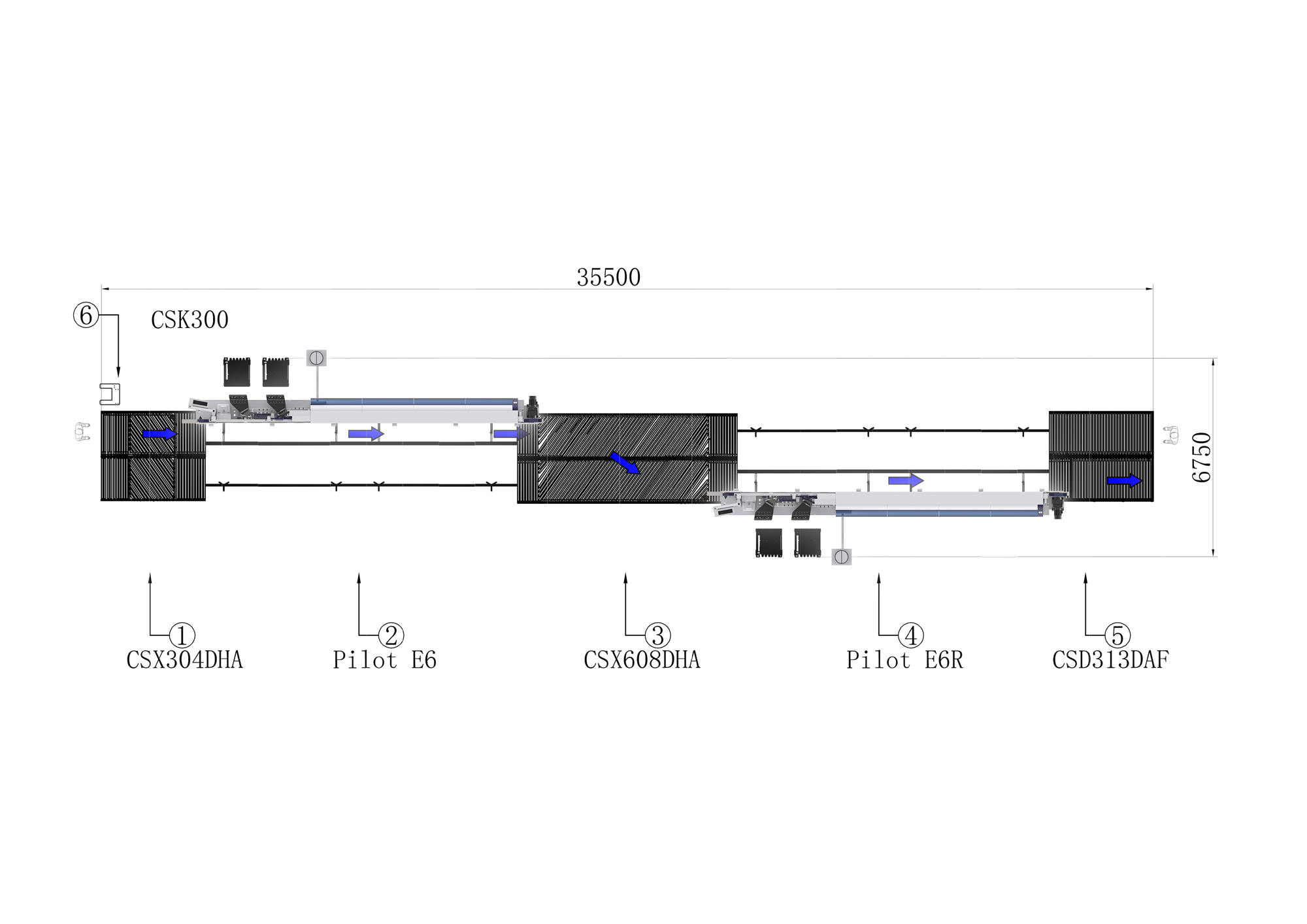

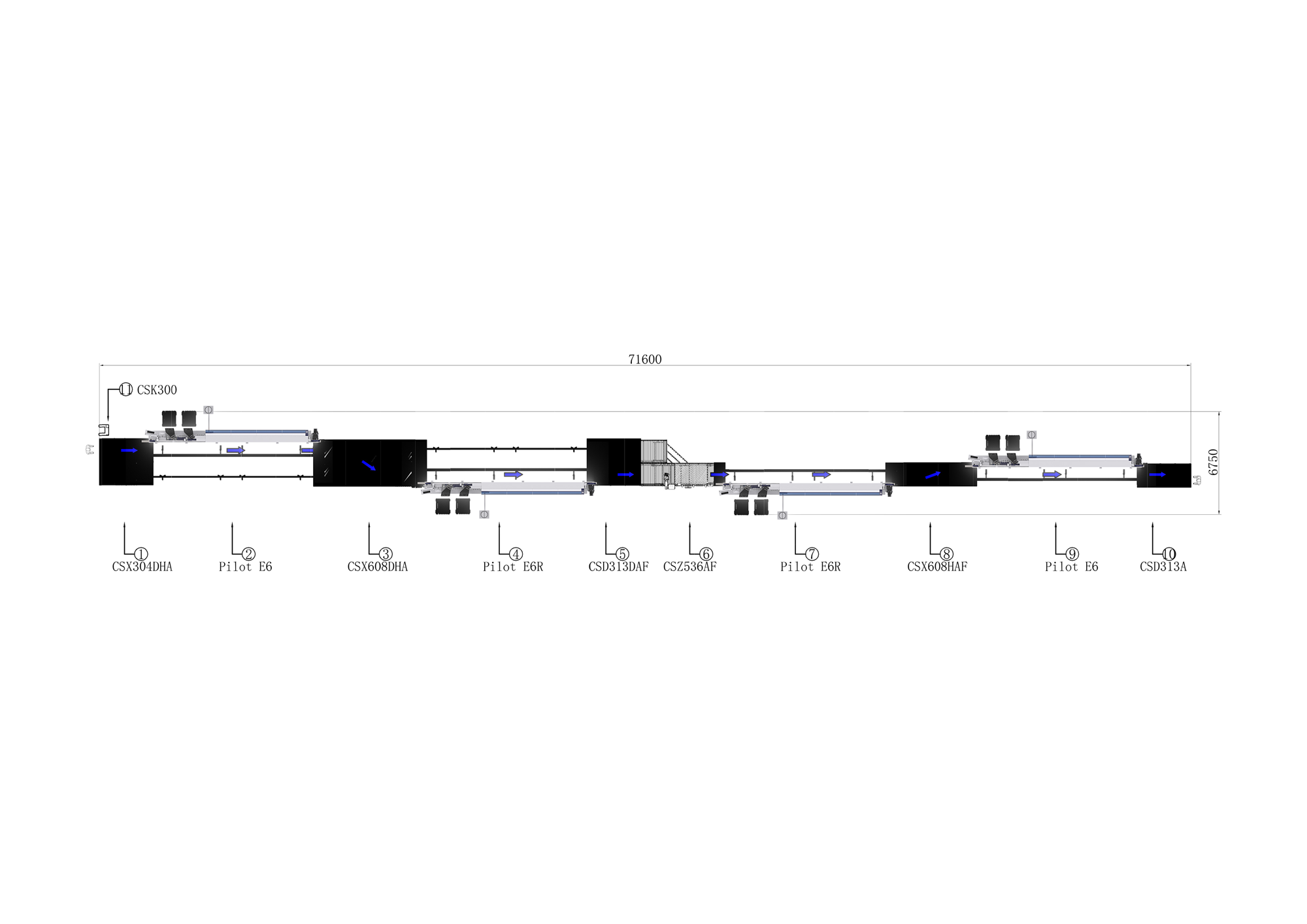

Panel Saw – The Core Machine for High-Precision Panel Cutting

The Caelus Panel Saw is designed specifically for precise cutting in panel furniture manufacturing, meeting the needs of cutting panels in multiple sizes and batches. It employs a heavy-duty, high-precision frame design, servo and linear drive technology, and an intelligent control system, maintaining extremely high stability and repeatability while cutting at high speeds.

Advantages of Caelus Panel Saw:

- Stable heavy-duty structure ensures long-term processing accuracy.

- Servo and high-response drive system enables fast and precise cutting.

- Intelligent optimization and layout functions improve material utilization.

- Can be connected to Auto Panel Storage and CNC machines to achieve automated panel cutting production lines.

- Supports everything from entry-level precision cutting to fully automated factory-level flexible processing.

Suitable for: Large furniture factories, customized flexible production lines, and multi-category panel processing enterprises.

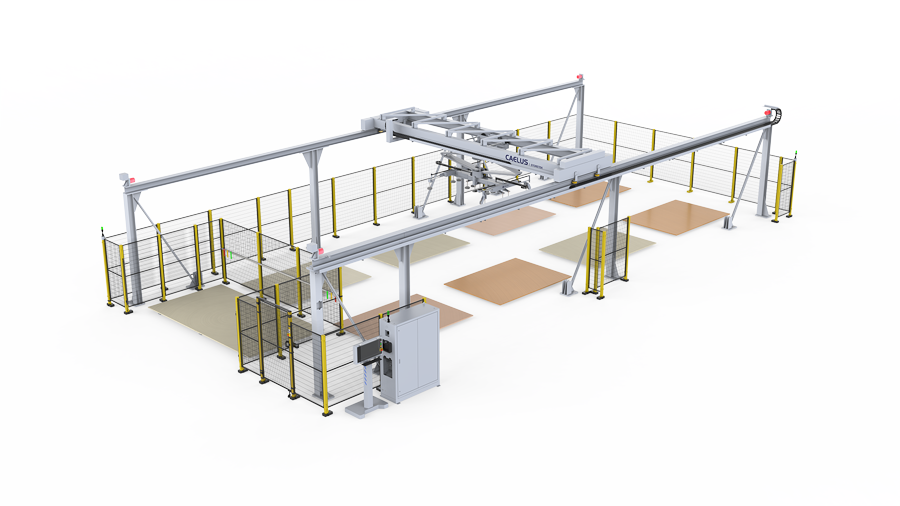

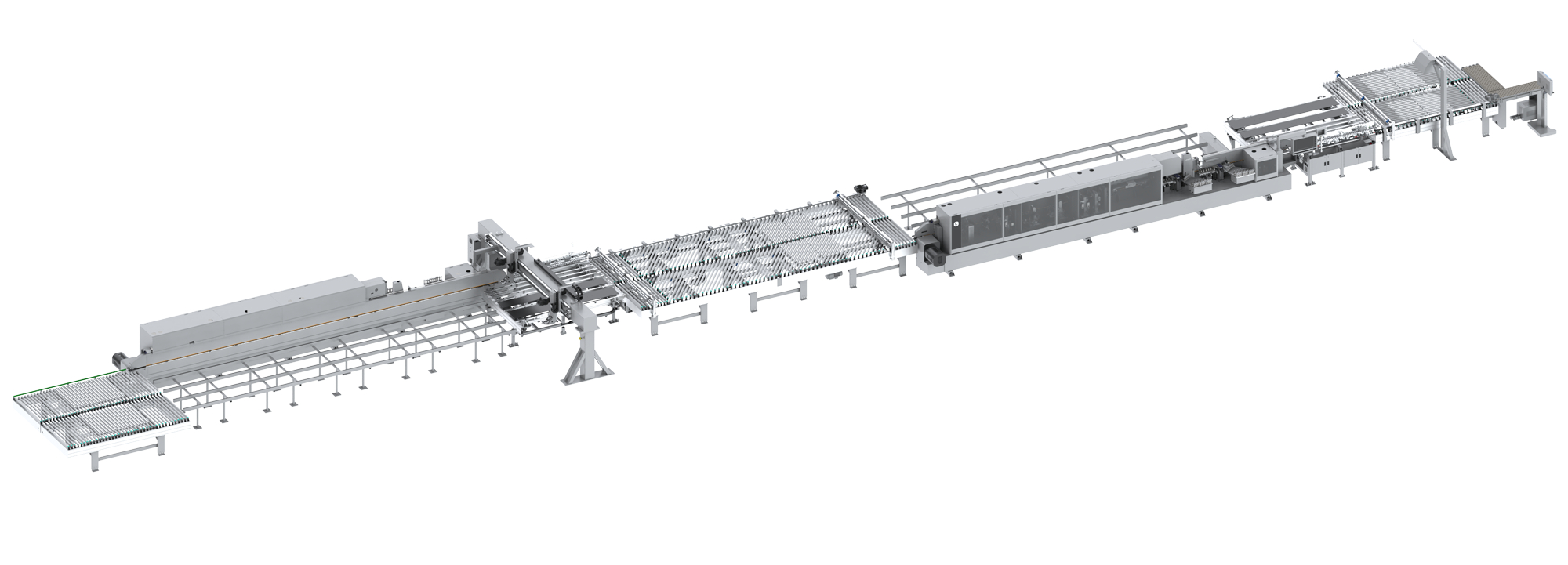

Auto Panel Storage System– Intelligent Panel Handling

Caelus Auto Panel Storage is not just a storage system, but also an intelligent panel logistics scheduling platform. It automatically completes panel sorting, storage, identification, path optimization, and transportation, ensuring continuous and efficient operation of the production line.

The core value of Caelus Automated Storage and Retrieval System (AS/RS):

* Significantly reduces manual material handling costs.

* Ensures continuous material supply to the Panel Saw and downstream production lines, increasing capacity by 10-30%.

* Automatically identifies, retrieves, and sorts materials, reducing human error (mixing, mis-picking, board damage).

* Improves material utilization and optimizes production rhythm.

* Integrates with the entire Panel Saw and Edge Bander series for closed-loop intelligent factory management.

This system is particularly suitable for manufacturing companies looking to improve factory efficiency, reduce reliance on manual labor, and build digital warehousing.

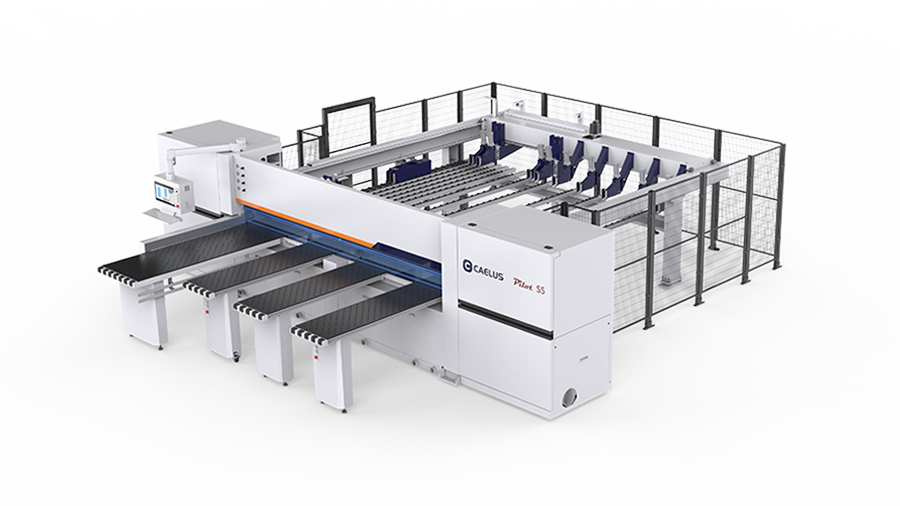

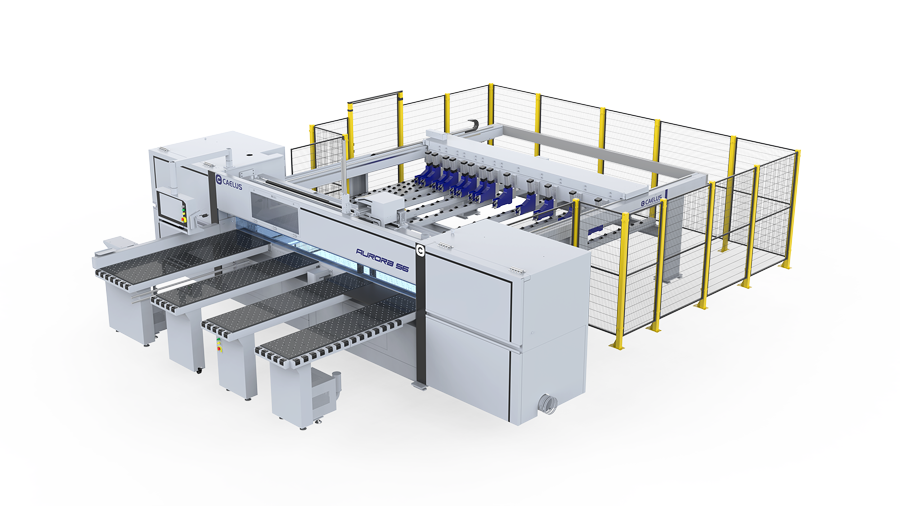

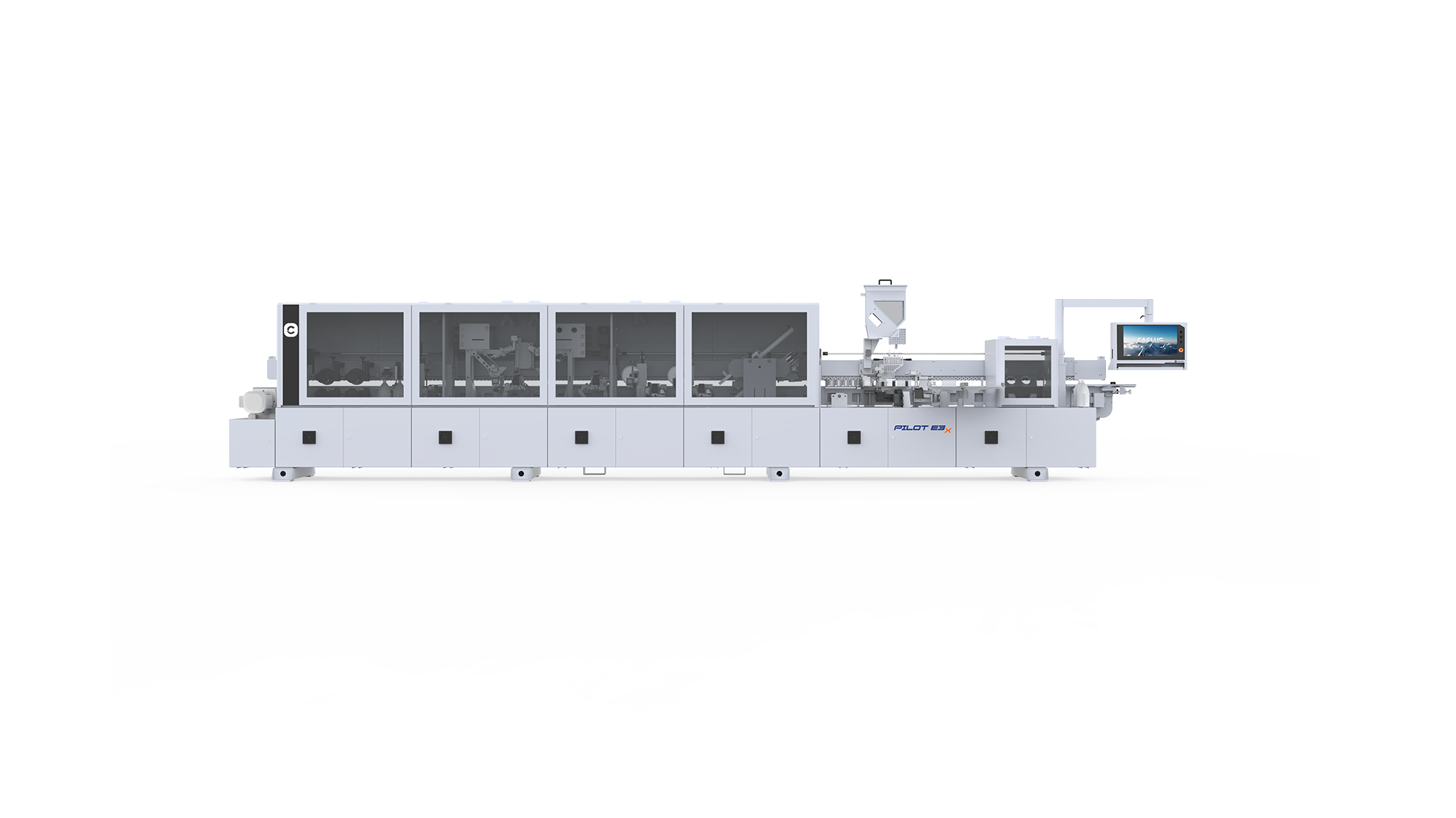

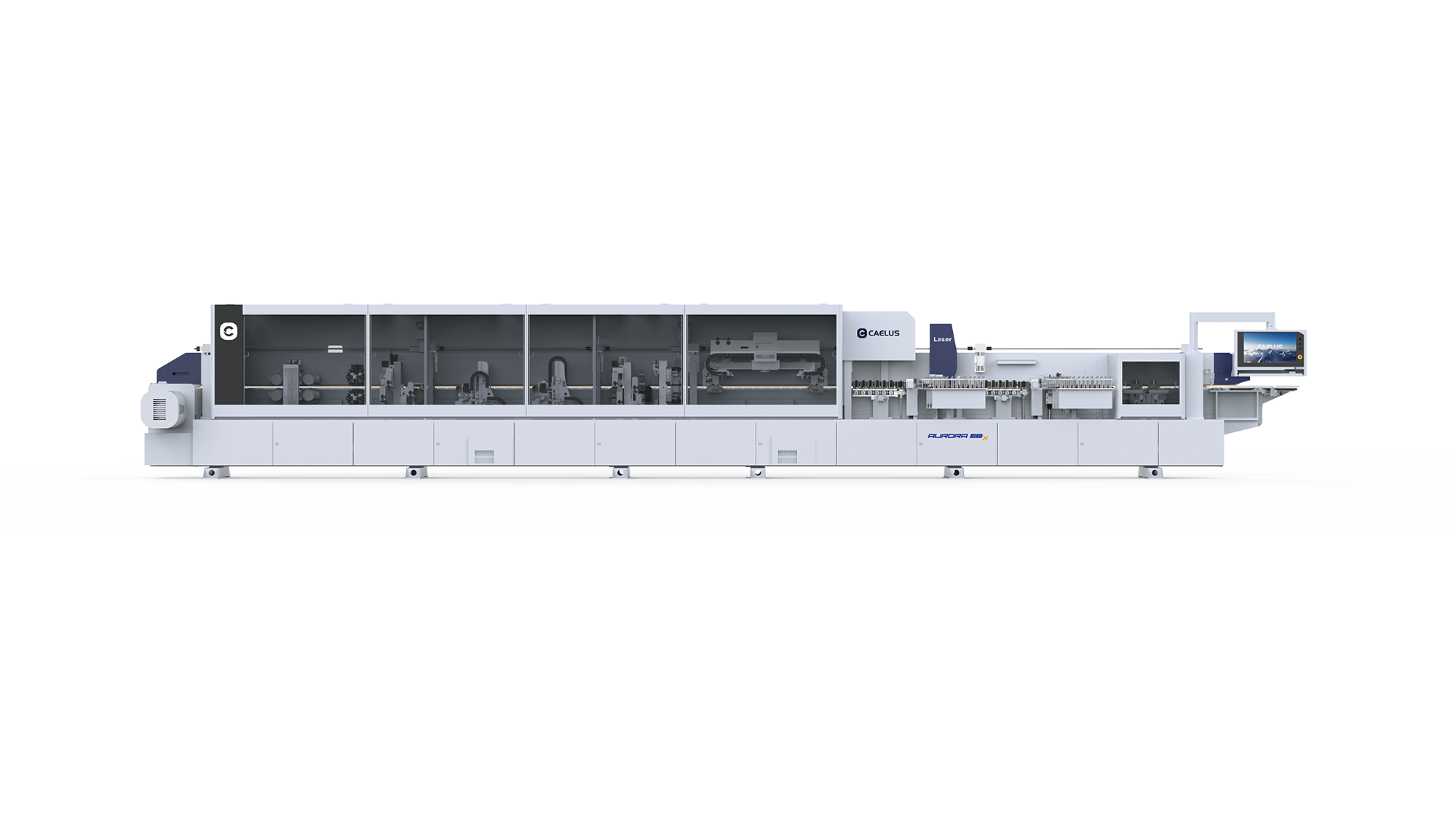

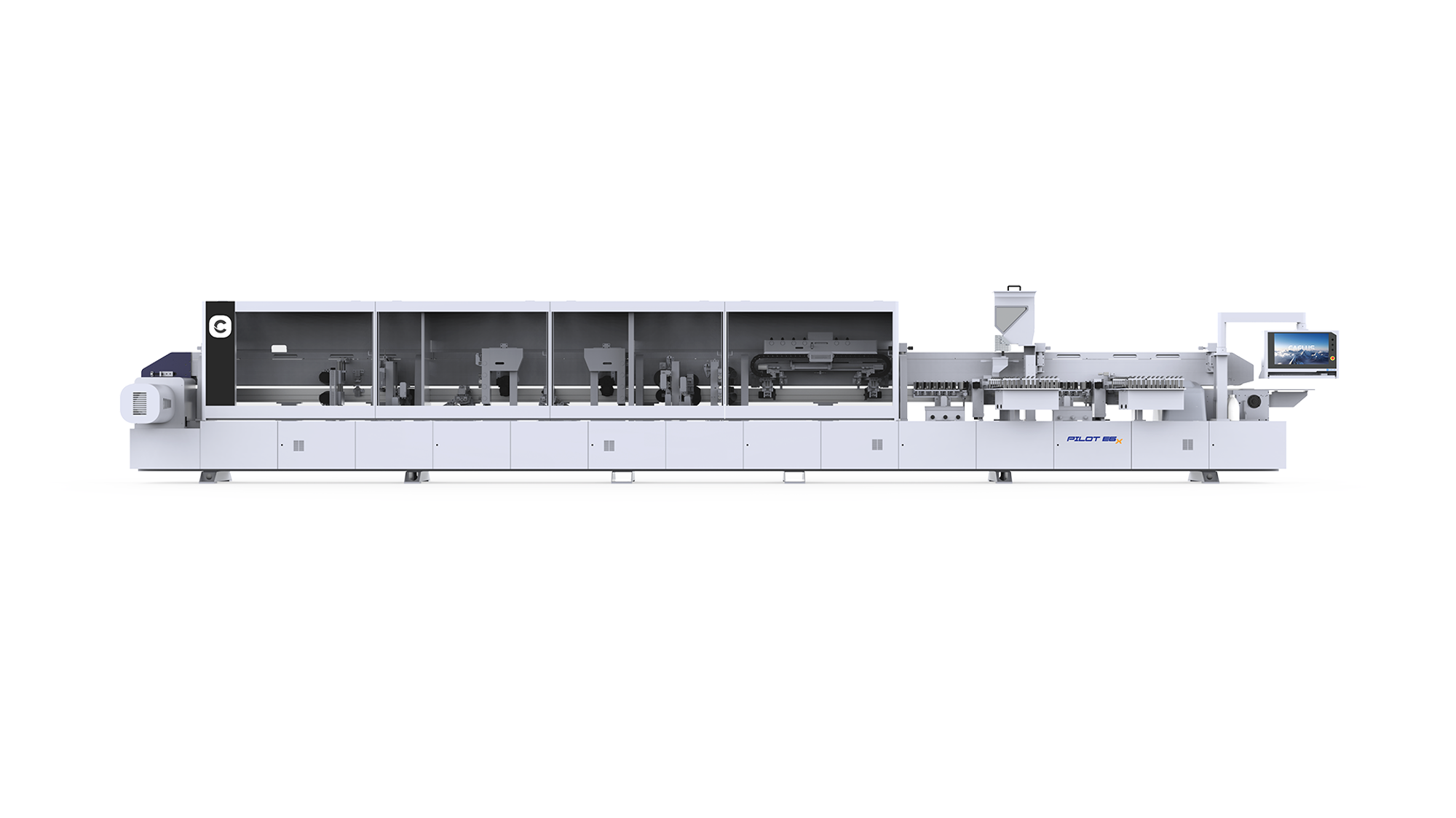

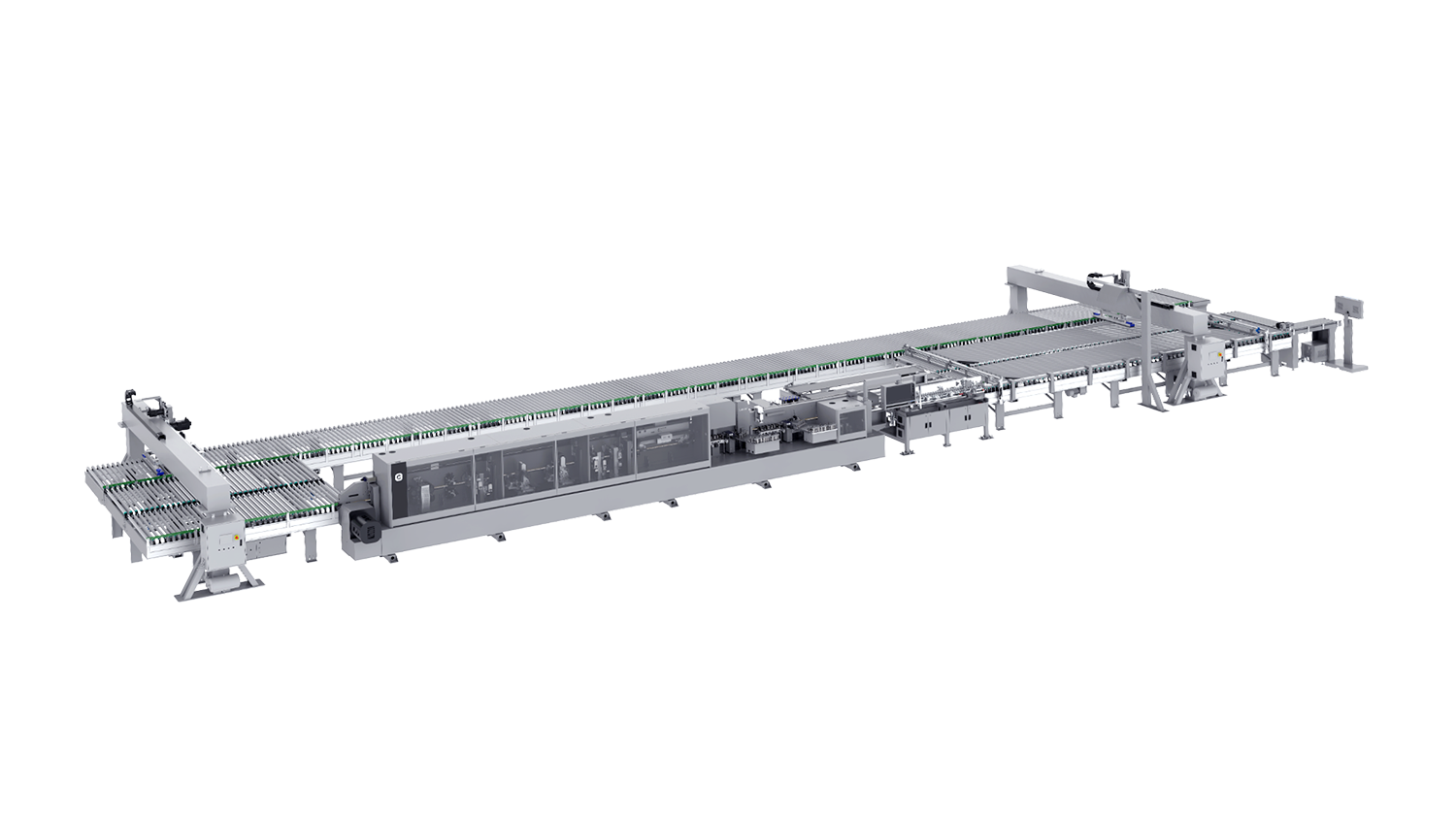

Edge Bander – A Key Process in High-Quality Furniture Forming

The Caelus Edge Bander features a heavy-duty structure, flexible order changeover, servo-driven high-precision control, and an intelligent maintenance architecture. It can handle various edge banding materials and complex processes, ensuring a smooth, strong, and aesthetically pleasing edge banding finish.

Advantages of the Caelus Edge Bander: Heavy-duty frame structure for more stable operation; Precise servo system control for stable bonding and high-precision edge trimming; High processing speed, adaptable to various edge banding processes and materials; Highly flexible order changeover capability, suitable for customized, small-batch, and mixed-batch production; Intelligent maintenance system and highly reliable electronic architecture reduce downtime and maintenance costs; Can be connected to CNC machines such as Panel Saws to form a complete edge banding processing center; Suitable for furniture manufacturers seeking high-quality edge banding effects and high-efficiency production.