In today's globalized furniture manufacturing market, manufacturers face unprecedented challenges. Consumer demand for customized furniture is growing, while simultaneously placing extremely stringent demands on product delivery times and quality details. For panel furniture, cutting the panels is only the first step; the true quality is often reflected in the edge treatment.

A saying in the panel processing industry goes: "Sawing determines the frame, edge banding determines the soul." Edge banding not only affects the aesthetics of the furniture but also directly impacts its moisture resistance, formaldehyde sealing effect, and service life. However, traditional edge banding processes often face problems such as low efficiency, high labor costs, visible glue lines, and high rework rates.

To overcome these bottlenecks, more and more modern factories are seeking manufacturing automation solutions. In this transformation process, choosing the right edge banding machine has become crucial for enhancing core competitiveness. This article will take you on an in-depth exploration of how intelligent edge banding machines are reshaping production processes and introduce how high-end machines, represented by Caelus, can help companies achieve a leap in production capacity.

What is a Intelligent Edge Banding Machine?

When we talk about intelligent edge banding machines, we are not referring to traditional machines that require manual panel feeding and have limited functions.

A intelligent edge banding machine is a high-precision industrial machine that integrates mechanical, electrical, pneumatic, and software control. It can automatically complete a series of complex processes such as pre-treatment, gluing, edge banding tape application, trimming, scraping, and polishing of the panel edges. More importantly, the "intelligence" lies in its ability to automatically recognize different panel thicknesses and different edge banding tape materials and adapt parameters accordingly.

In modern production, an intelligent fast banding machine is not just an executor, but also a manager. Through high-precision sensors and servo systems, it ensures that the glue amount for every meter of edge banding is controlled to the gram, and the error of each trimming cut is controlled at the micron level. This high degree of consistency is something that pure manual operation can never achieve.

For factories pursuing high quality and high efficiency, a intelligent edge banding machine is no longer an "option," but a "necessity." It serves as the bridge connecting panel cutting and drilling/packaging, and is the heart that ensures the smooth operation of the entire automated production line.

How do intelligent edge banding machines improve furniture production efficiency?

Edge Banding Machines Improve Furniture Production

In furniture manufacturing, efficiency is profit. The performance of the Edge Bander directly determines the speed of panel processing.

A Dual Leap in Speed and Precision

Traditional edge banding machines are often limited by their mechanical structure, resulting in slower feed speeds and stability problems at high speeds. The new generation of intelligent fast banding machines, however, achieves a qualitative leap through optimized mechanical structures and control algorithms.

For example, high-end intelligent edge banding machines can achieve feed speeds of up to 30-40 meters/minute or even higher. This means that factories can process more panels in a given time. At the same time, operating a high-speed servo drive system, the machine can maintain a very high motion response frequency during high-speed operation, ensuring that trimming and other operations remain precise and accurate during fast edge banding, thus greatly reducing material waste and rework time caused by processing defects.

Reducing Reliance on Manual Labor, Moving Towards Manufacturing Automation

Rising labor costs and a shortage of skilled workers are common pain points in the industry. Intelligent edge banding machines significantly reduce the reliance on operator skills through highly automated functions.

Automatic tape change: It doesn't like manual machine need shutdown to change edge banding tape; multi-channel magazines allow for automatic switching.

Automatic adjustment: For panels of different thicknesses, the system can adjust the pressure beam height and trimming knife position with a single click, eliminating the need for repeated manual adjustments.

This realization of manufacturing automation not only frees workers from heavy physical labor but also minimizes error rates. A highly automated edge banding line often requires only one operator for monitoring, greatly improving labor efficiency.

The Revolutionary Improvement of Intelligent Edge Banding Machines for Furniture Manufacturing: Caelus's Solution

Edge Bander's High Speed Horizontal Meglev End-cutting

Intelligent edge banding machines have completely revolutionized traditional edge banding methods in furniture production through automation and intelligent control. They not only improve the accuracy and consistency of edge banding but also increase production speed and efficiency in large-scale production. As a leader in this field, the Caelus automatic edge banding machine perfectly exemplifies this technological transformation.

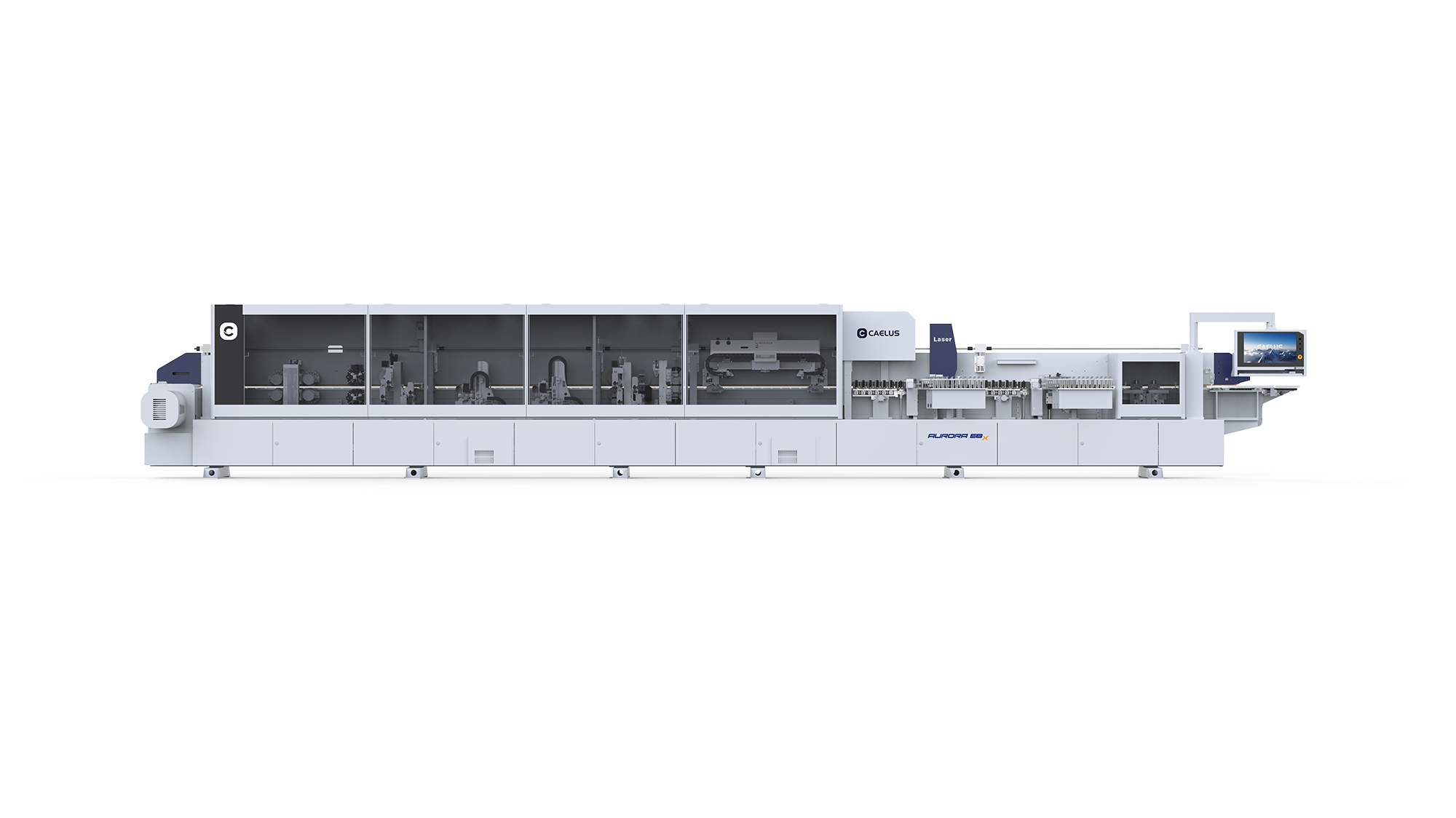

Caelus Automatic Edge Banding Machine: Born for High-End Manufacturing

The Caelus automatic edge banding machine is a high-performance machine specifically designed for the modern furniture manufacturing and panel processing industries. It is suitable not only for large-scale cabinet and wardrobe production lines but also perfectly meets the diverse needs of office furniture and high-end custom furniture manufacturing.

With its high precision, high efficiency, strong stability, and high level of intelligence, the Caelus edge banding machine has become a core machine in many intelligent factories. Its design was initially conceived to solve the problems of insufficient rigidity, closed systems, and complex operation of traditional machines.

Technological Positioning and Full-Process Processing

In Caelus's solution, edge banding is no longer simply "adhesion." The Caelus edge banding machine can complete the entire edge processing process:

Pre-milling: Eliminates ripples and chipping left by sawing, ensuring the edges of the panel are flat and perpendicular.

Gluing and Pressing: It supports EVA and PUR adhesives, and even laser edge banding technology, ensuring strong adhesion and extremely fine glue lines.

Front and Rear Trimming and Edge Finishing: Uses high-precision servo motors to accurately cut off excess edge banding tape.

Corner Rounding: It rounds the four corners of the panel for a smooth feel.

Scraping and Polishing: It removes tool marks and restores the gloss of the edge banding tape.

The automated execution of this entire process effectively replaces tedious manual finishing, providing a highly consistent and stable intelligent solution.

Wide Range of Applicable Industries

Whether it's panel furniture factories pursuing ultimate efficiency, custom furniture manufacturers pursuing personalized details, or office furniture and commercial space furniture production requiring extremely high durability, Caelus can provide a matching solution.

Key Factors for Choosing an Intelligent Edge Banding Machine

Faced with the dazzling array of Edge Banders on the market, how should factory owners make a wise choice? The following three factors are crucial.

Edge Banding Precision and Stability

The core of an edge banding machine lies in "stability." The rigidity of the machine body directly determines the amount of vibration during processing. The less vibration, the flatter the edge banding effect. When choosing, attention should be paid to whether the machine uses a high-strength steel frame structure. Furthermore, the profiling accuracy of the trimming unit directly affects the feel of the finished product.

Automation Features

In the selection of an intelligent edge banding machine, software functions are just as important as hardware.

Automatic thickness adjustment: Can the pressure beam height be automatically adjusted via a servo system?

Automatic glue changing system: Does it support quick switching between EVA and PUR adhesives? PUR adhesive has become the standard for high-end furniture due to its excellent water resistance and heat resistance.

Automatic speed adjustment: Can the machine automatically reduce or increase the transfer speed according to complex processes (such as profile tracking)?

Maintenance and Operation

Even the most advanced machine will become a burden to the factory if it is complex to operate and difficult to maintain. An excellent human-machine interface (HMI) should be intuitive and easy to understand, with self-diagnostic functions. At the same time, cleaning and lubrication maintenance of the machine should be as convenient as possible.

How to Choose the Right Intelligent Edge Banding Machine Model?

There is no best machine, only the most suitable machine. Based on the specific needs of panel processing, we can consider the following dimensions.

Adaptability to Production Scale and Needs

Small customized factories: Fragmented orders, frequent order changes. Choose a model with fast belt change speed and a flexible system, such as Caelus's Pilot series.

Large-scale mass production factories: Large order volume, pursuing maximum capacity. Choose a heavy-duty model equipped with high-speed motors and multi-channel material bins, such as Caelus's Aurora series.

High-Performance Edge Banding and Multifunctionality

If your products include a large number of lacquered panels, high-gloss panels, or acrylic panels, you need a machine that can handle sensitive surfaces to avoid scratching. If curved edge banding is involved, a specialized processing center or manual assistance machine is required, but most panel furniture mainly relies on linear intelligent fast banding machines.

Brand and Manufacturer

Choosing an Edge Bander is choosing a partner. When evaluating a brand, you should not only look at technical parameters but also at its industry reputation and after-sales support capabilities. A manufacturer that can provide a quick response in case of machine failure can save you significant production downtime losses.

Industry Trends in Intelligent Edge Banding Machines

Future Technological Development: Intelligence and the Internet of Things

The future of furniture manufacturing will be data-driven. Intelligent edge banding machines are developing towards AI and IoT (Internet of Things). Predictive Maintenance: Machines monitor data such as motor temperature and vibration in real time through sensors, providing warnings before failures occur.

Cloud Connectivity: Production data is uploaded to the cloud in real time, allowing managers to monitor production capacity anytime, anywhere.

Laser and Seamless Edge Banding Technology

With consumers' increasing demands for aesthetics, "zero glue line" technology, represented by laser edge banding, is becoming increasingly popular. This technology uses a high-energy laser beam to instantly melt the functional layer of the edge banding tape, achieving perfect fusion between the panel and the edge banding tape, completely eliminating the black lines produced by traditional hot-melt adhesives.

Why Choose Caelus Intelligent Edge Banding Machines?

Among numerous brands, Caelus stands out with its profound technological expertise and deep understanding of the industry.

Brand Advantages and Innovative Technology

Caelus is not just a machine manufacturer, but also a provider of Manufacturing Automation solutions.

Precision Drive and High-Rigidity Frame: All models of edge banding machines use high-strength steel frame structures, steel pressure beams, and guide rail systems. This "heavy-duty" design ensures ultra-high stability of the machine during long-term high-speed operation.

Full Servo System Coverage: Caelus edge banding machines are equipped with servo or linear drive systems, achieving high repetitive positioning accuracy.

Efficiency and Reliability: Pilot and Aurora Series

Caelus offers different product lines to meet the needs of different customers:

Pilot Series (e.g., Pilot E6/E6x): Designed for high-capacity production. Equipped with a 12+12 channel servo edge banding magazine, supporting automatic intelligent switching of multiple specifications of edge banding tapes. This means that the machine requires almost no downtime for tape changes when processing complex orders, greatly improving flexible production capabilities.

Aurora Series (e.g., Aurora E8/E8x): High-end flagship. Uses linear motor drive, with processing speeds up to 42 m/min. Its high-speed corner rounding processing speed can reach 36 m/min, making it a production powerhouse in high-volume production environments.

System Integration Capabilities

Another major advantage of the Caelus intelligent edge banding machine is its powerful integration capabilities. It's not just a standalone edge banding machine; it can also seamlessly integrate with Caelus's Caelus Panel Saw, StoreTek 5 automatic storage system, and CNC machines. Through the MES system, factories can build a fully automated production line from panel cutting to edge banding and drilling, achieving true data interoperability and synchronized workflow.

FAQ

To help you make a clearer purchasing decision, we have compiled the most frequently asked questions about edge banding machines in the furniture manufacturing industry.

Q1: What is the biggest difference between a regular edge banding machine and an "intelligent edge banding machine"?

A: The biggest difference lies in the "level of automation" and "flexibility." Regular edge banding machines usually require manual adjustment of the pressure beam height, glue pot replacement, or trimming knife position, which is time-consuming and relies on experience. Intelligent edge banding machines (such as the Caelus series) are equipped with servo drive systems and intelligent control software. They can automatically identify panel thickness, switch edge banding tapes with one click, automatically adjust the glue application amount, and even perform automatic fault diagnosis. This means higher processing accuracy, lower human error rates, and faster response capabilities for small-batch customized orders.

Q2: Is laser edge banding necessary?

A: This depends on the product positioning of the furniture manufacturer. Caelus laser(内链https://www.caelus-intel.com/product/high-speed-intelligent-edge-banding-machine-aurora-e8x.html) edge banding achieves a perfect "zero glue line" effect and excellent appearance, but the machine and edge banding tape costs are higher. For most factories that pursue high quality but are also concerned about cost-effectiveness, operating an Edge Bander with PUR functionality can achieve results very close to laser edge banding, with lower operating costs.

Conclusion:Intelligent Edge Banding Machines Power the Future of Furniture Manufacturing

Under the wave of Industry 4.0, furniture manufacturing is undergoing a profound transformation. As a key link in this transformation, the role of intelligent edge banding machines has long surpassed the scope of mere machinery.

It helps furniture manufacturers achieve the leap from "manufacturing" to "intelligent manufacturing": improving efficiency and reducing costs through intelligent fast banding machines; enhancing product quality and grade through precise Edge Bander technology; and strengthening the company's market responsiveness through highly integrated manufacturing automation systems.

Looking ahead, with continuous technological advancements, edge banding machines will become intelligenter, more environmentally friendly, more interconnected, and better tailored to needs. Choosing a partner like Caelus, with forward-looking technology and reliable quality, will be the wisest investment for every furniture company aiming for the future.